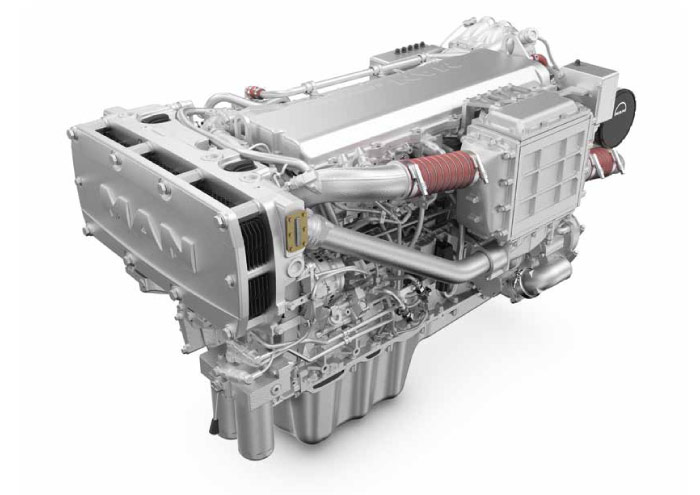

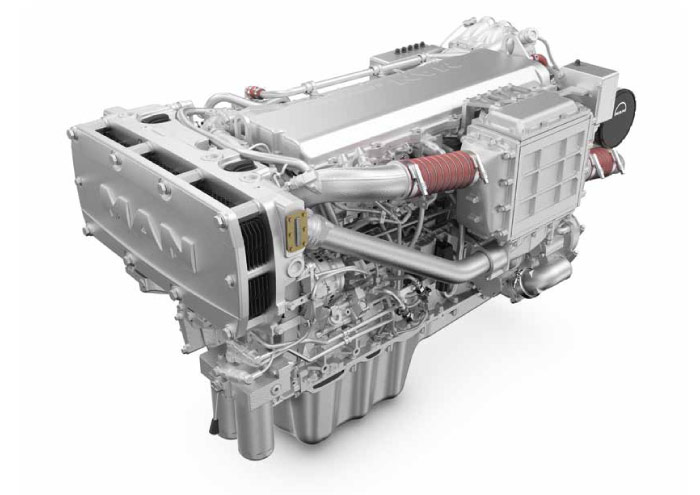

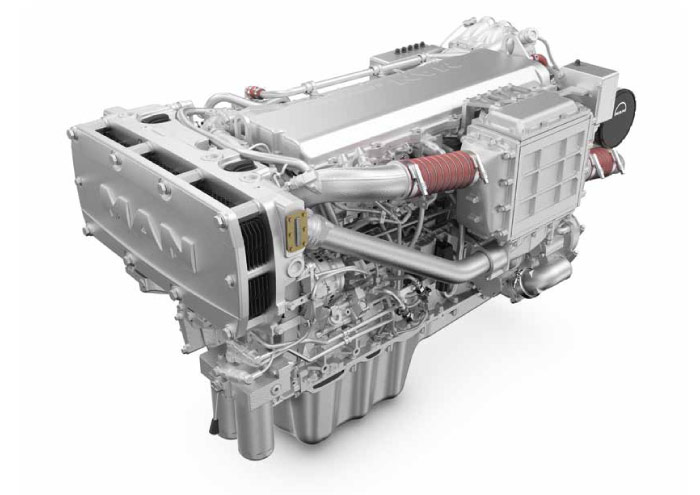

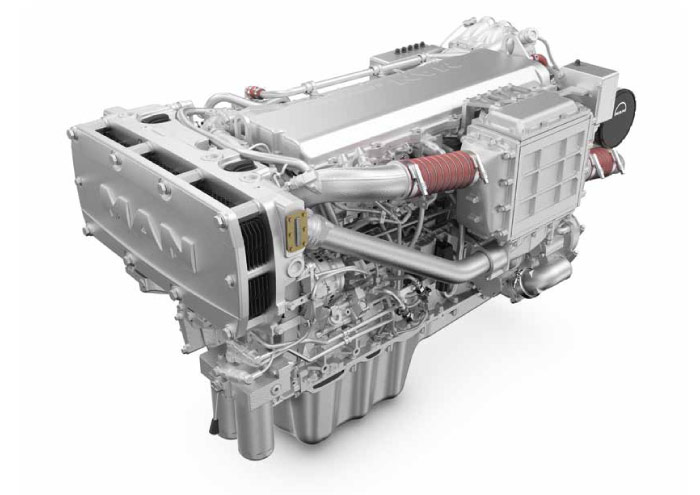

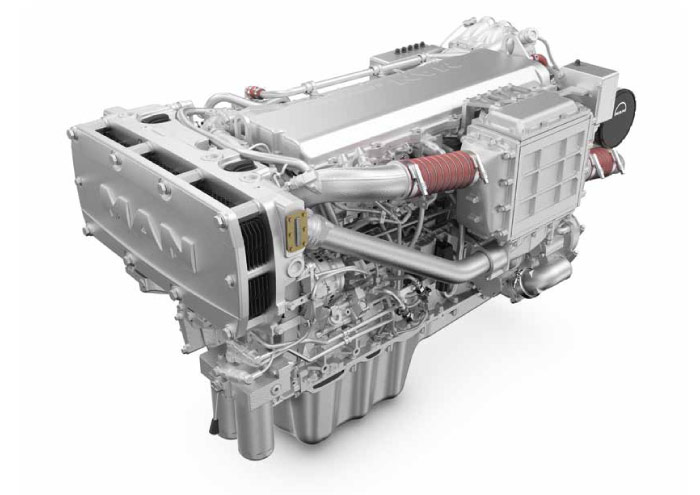

MAN Marine Engines

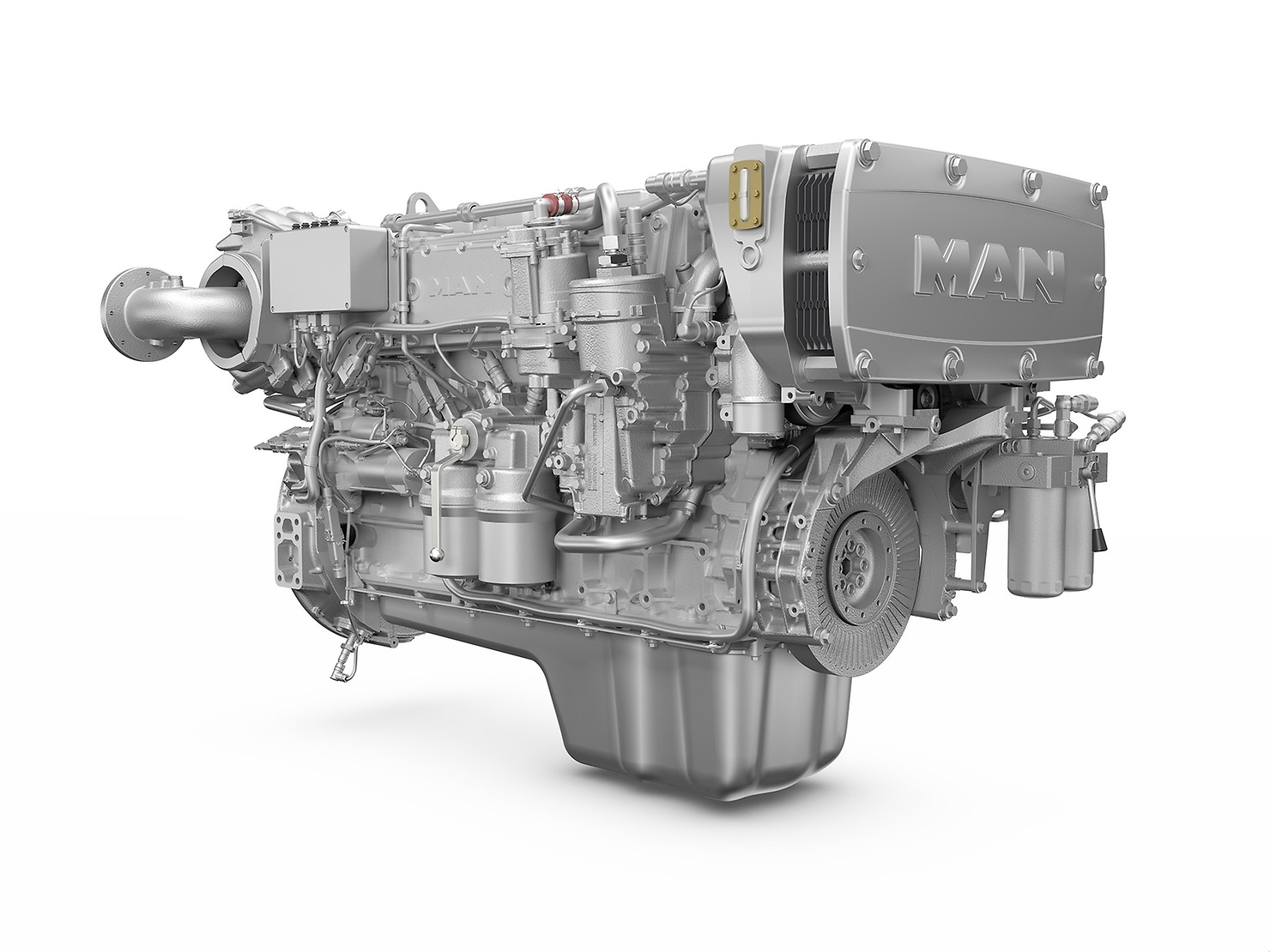

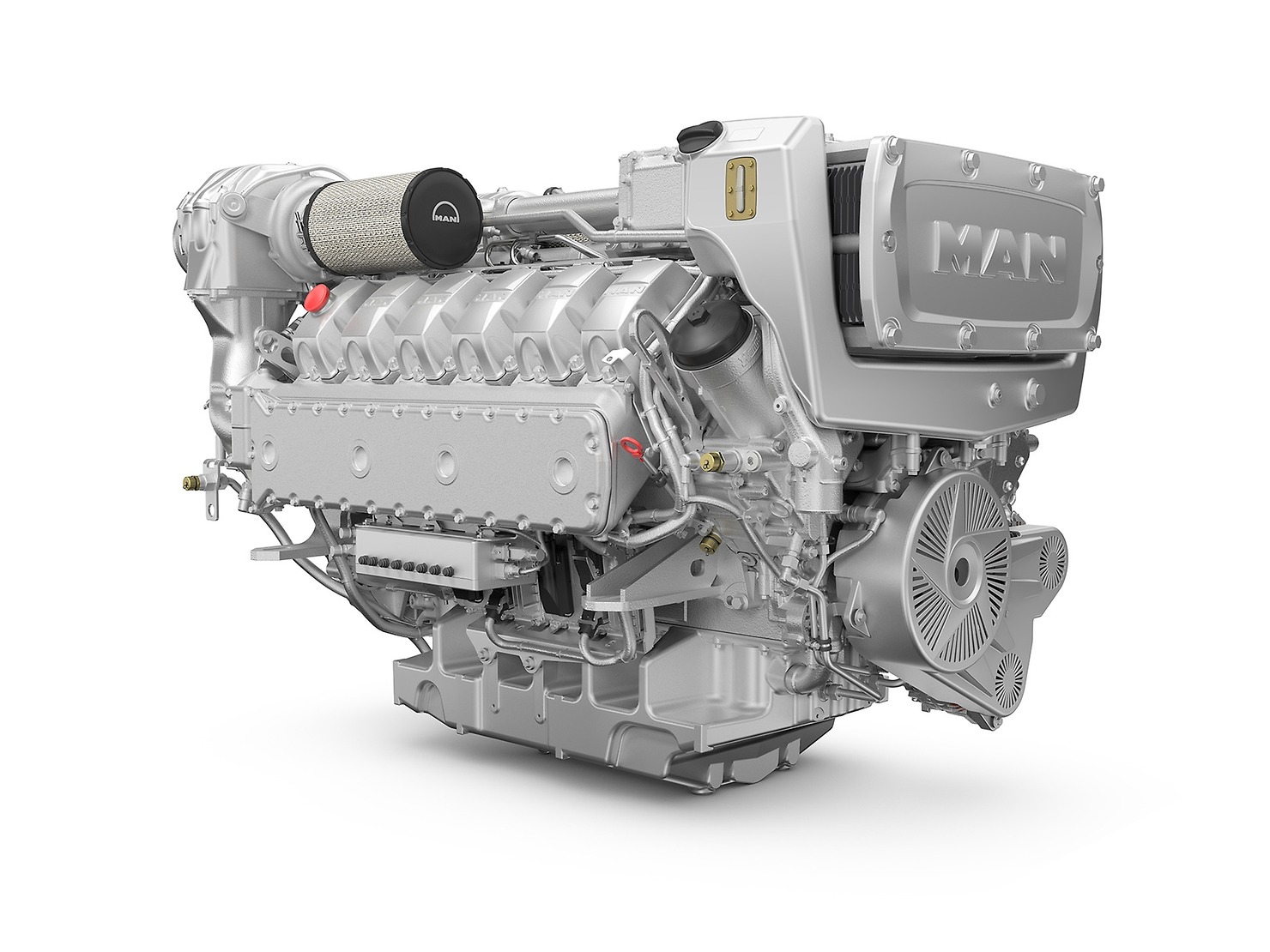

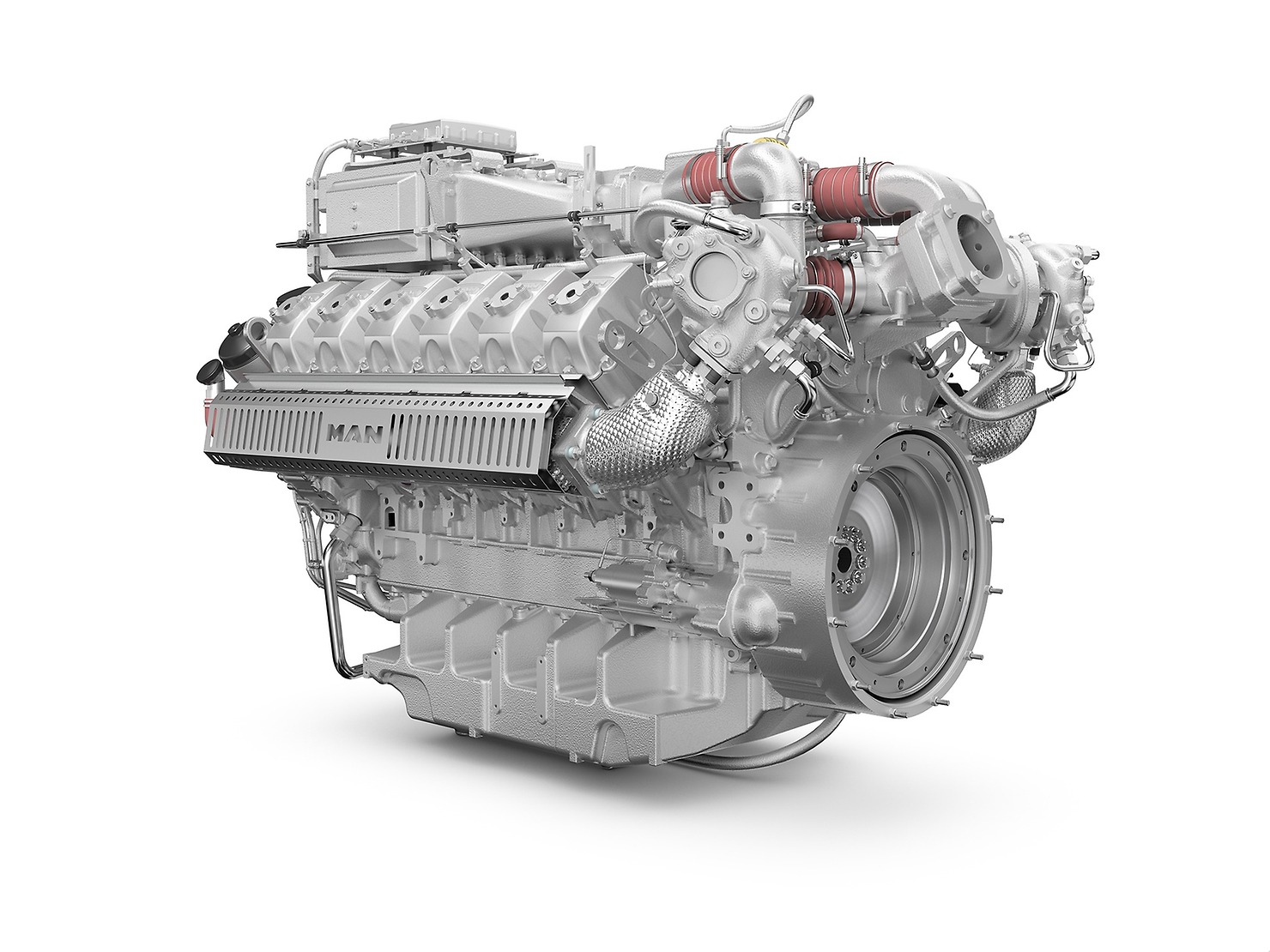

MAN Engines offers a wide range of high-speed four-stroke diesel engines that provide a power spectrum from 147 kW to 735 kW (200 HP to 1,000 HP) in heavy-duty operation. In medium-duty operation, the power range extends from 412 kW to 1,066 kW (560 HP to 1,450 HP). Engine programme with guaranteed efficiency: In light-duty operation (up to 1,000 hrs/year at 20 % full load share), the power range of the 6-, 8- and 12-cylinder engines extends from 537 kW to 1,397 kW (730 HP to 1,900 HP).

MAN marine engines are characterised by powerful acceleration with extremely economical fuel consumption. Their advantages predominantly lie in their outstanding power output combined with compact dimensions. The engines are delivered ready for installation and are optimally designed for the respective application and operating conditions – the robust lightweights convince in every respect and in every application.

Now Offering IMO III Certified Engines

-

Inline 6: 200HP – 850HP

-

V8: 600HO – 1,300HP

-

V12: 749HP – 2000HP

-

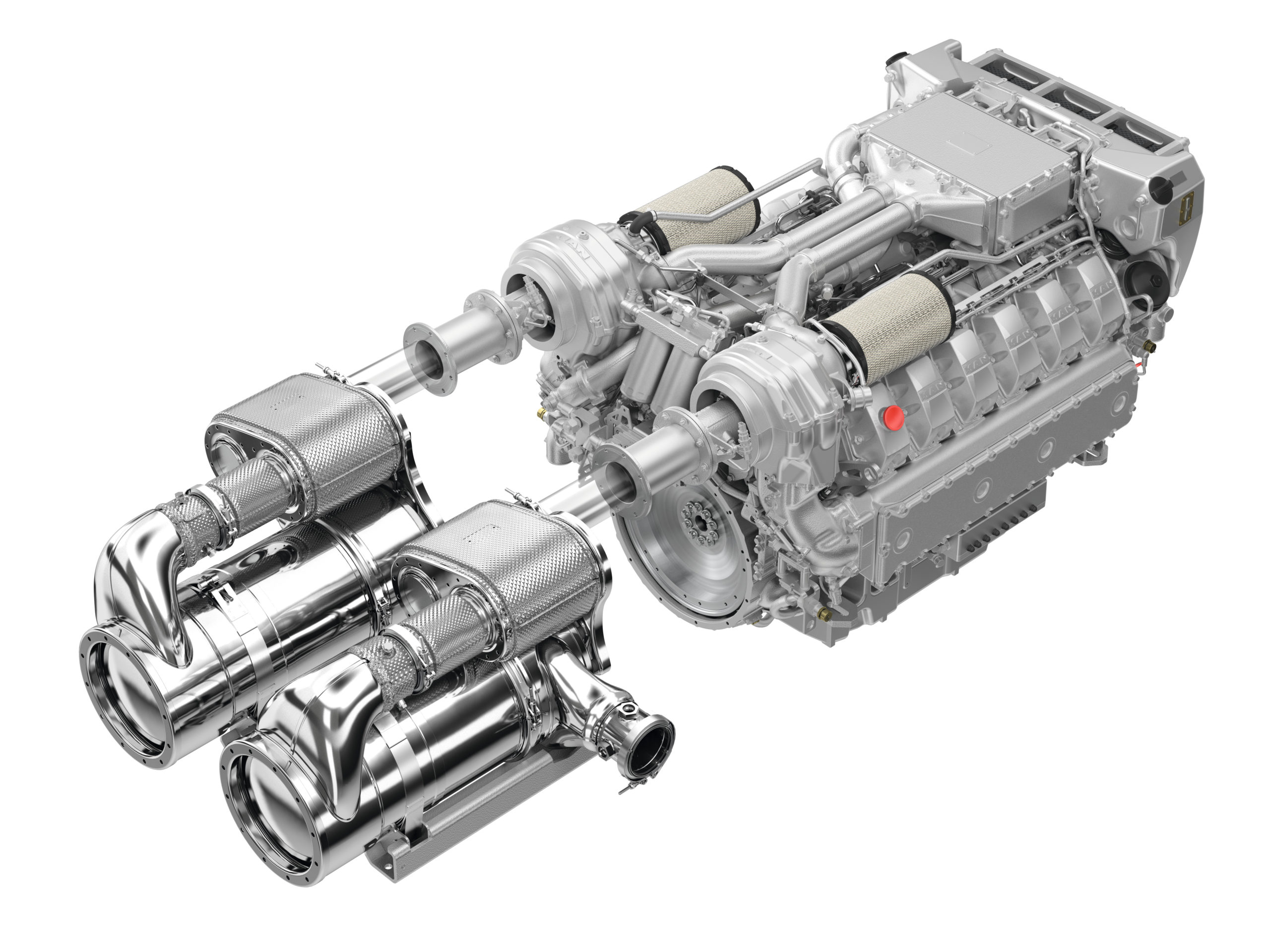

Compact & versatile SCR system

-

Superior fuel economy

-

Reliable electronic operation

Products:

D2862LE441

IMO: II

Output: 1000 hp @ 1,800 rpm

Dry Weight: 2,270 kg

Dimensions:

Length: 2,130 mm

Width: 1,153 mm

Height: 1,230 mm

D2862LE431

IMO: II

Output: 749 hp @ 1,800 rpm

Dry Weight: 1,215 kg

Dimensions:

Length: 1,795 mm

Width: 986 mm

Height: 1,096 mm

D2676LE431

IMO: II

Output: 440 hp @ 1,800 rpm

Dry Weight: 1,215 kg

Dimensions:

Length: 1,795 mm

Width: 986 mm

Height: 1,096 mm

D2676LE421

IMO: II

Output: 520 hp @ 1,800 rpm

Dry Weight: 1,215 kg

Dimensions:

Length: 1,795 mm

Width: 986 mm

Height: 1,096 mm

D2676LE422

IMO: II

Output: 650 hp @ 2,100 rpm

Dry Weight: 1,215 kg

Dimensions:

Length: 1,795 mm

Width: 986 mm

Height: 1,096 mm

D2676LE443

IMO: II

Output: 730 hp @ 2,300 rpm

Dry Weight: 1,215 kg

Dimensions:

Length: 1,795 mm

Width: 986 mm

Height: 1,096 mm

D2676LE423

IMO: II

Output: 800 hp @ 2,300 rpm

Dry Weight: 1,215 kg

Dimensions:

Length: 1,795 mm

Width: 986 mm

Height: 1,096 mm

D2868LE431

IMO: II

Output: 680 hp @ 1,800 rpm

Dry Weight: 1,780 kg

Dimensions:

Length: 1,745 mm

Width: 1,153 mm

Height: 1,243 mm

D2868LE443

IMO: II

Output: 900 hp @ 2,100 rpm

Dry Weight: 1,780 kg

Dimensions:

Length: 1,745 mm

Width: 1,153 mm

Height: 1,243 mm

D2868LE426

IMO: II

Output: 1,000 hp @ 2,300 rpm

Dry Weight: 1,780 kg

Dimensions:

Length: 1,745 kg

Width: 1,153 kg

Height: 1,243 kg

PROPULSION ENGINES (VARIABLE SPEED):

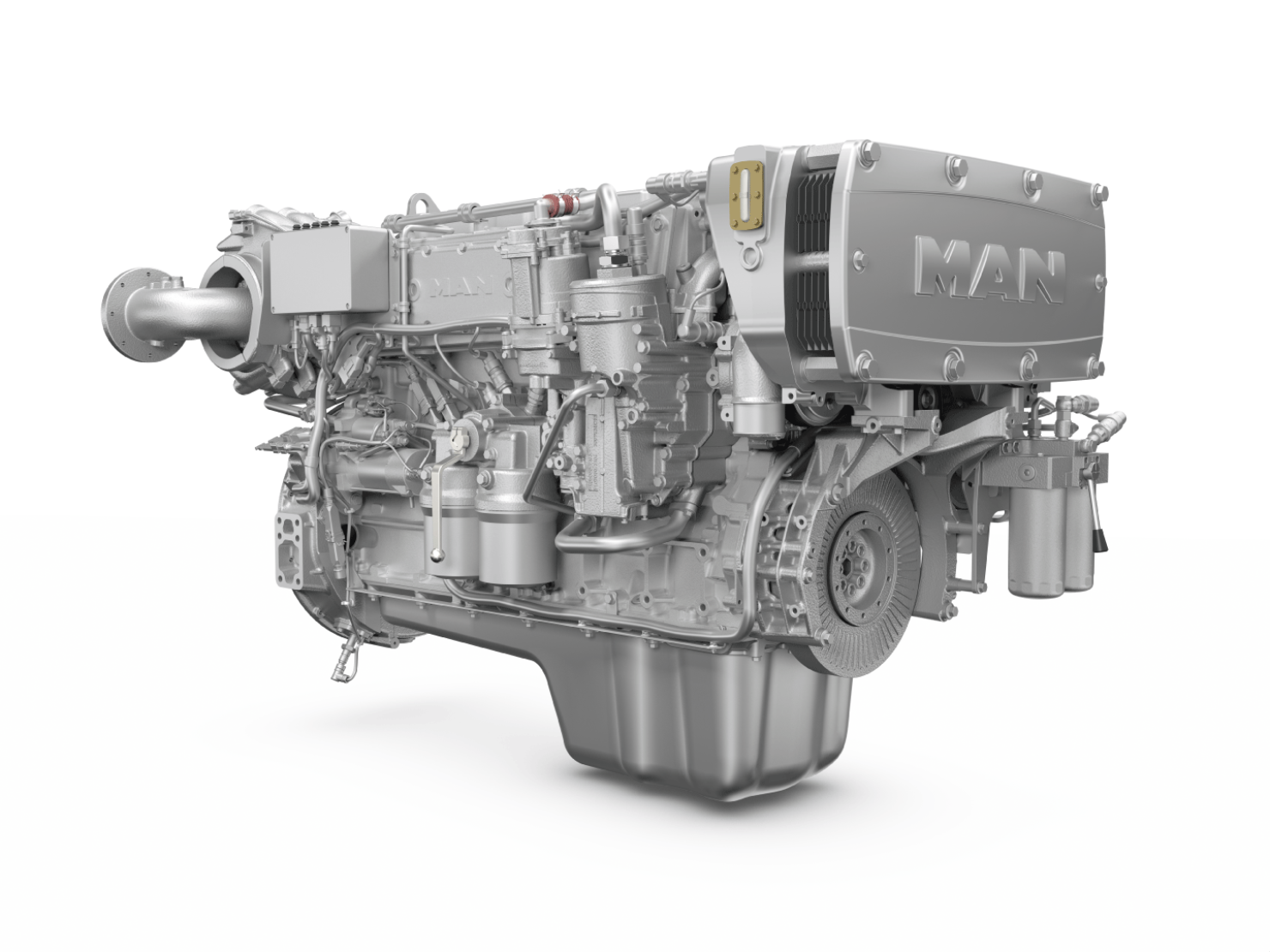

MAN D2676 (light / medium / heavy duty)

Cylinders: 6

Displacement: 12.4-liter

Bore: 126 mm

Stroke: 166 mm

Output: 537 – 625 kW / 412 – 478 kW / 147 – 382 kW

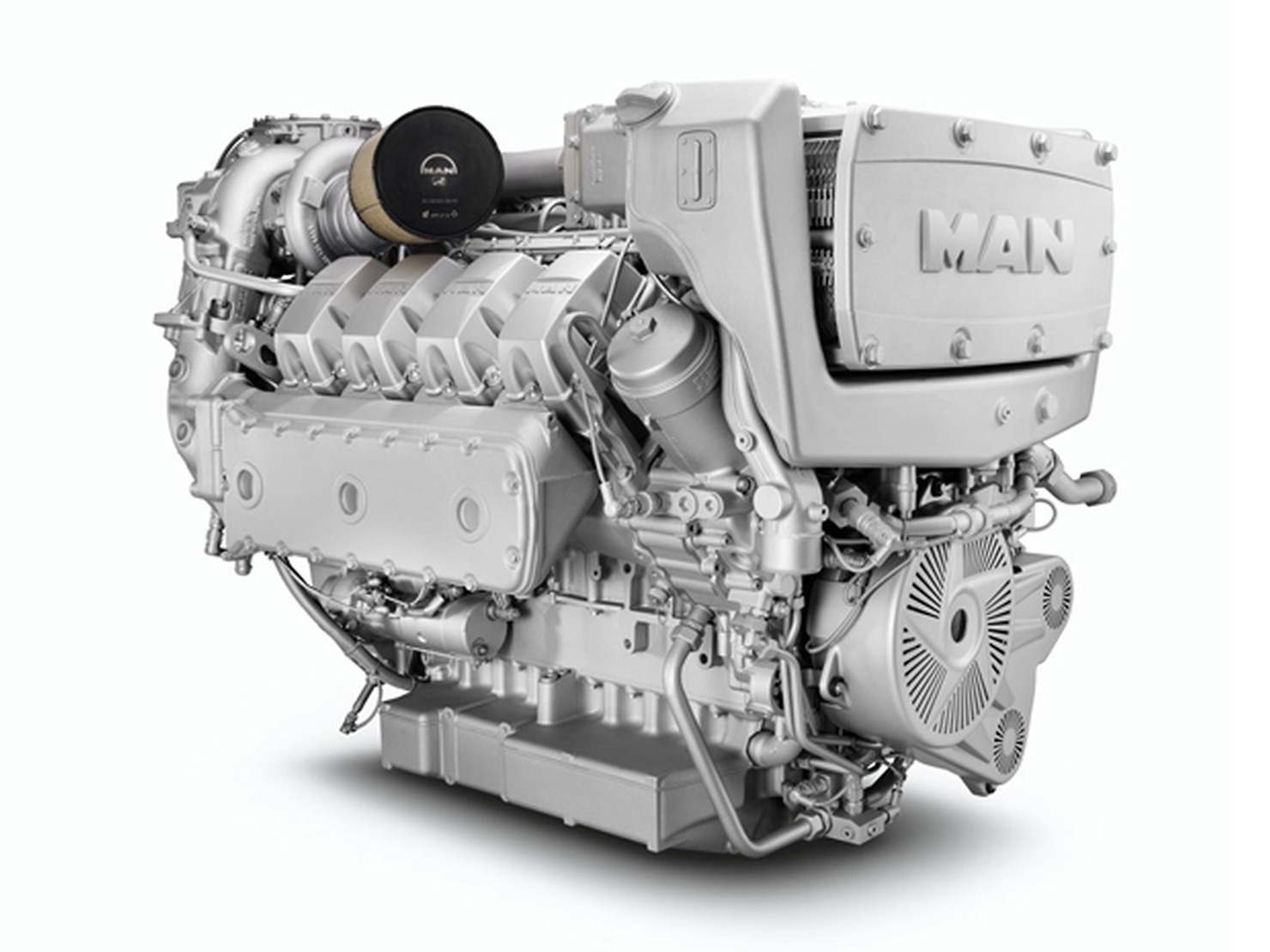

MAN D2868 (light / medium / heavy duty)

Cylinders: 8

Displacement: 16.2-liter

Bore: 128 mm

Stroke: 157 mm

Output: 735 – 956kW / 588 – 662 kW / 441 – 500 kW

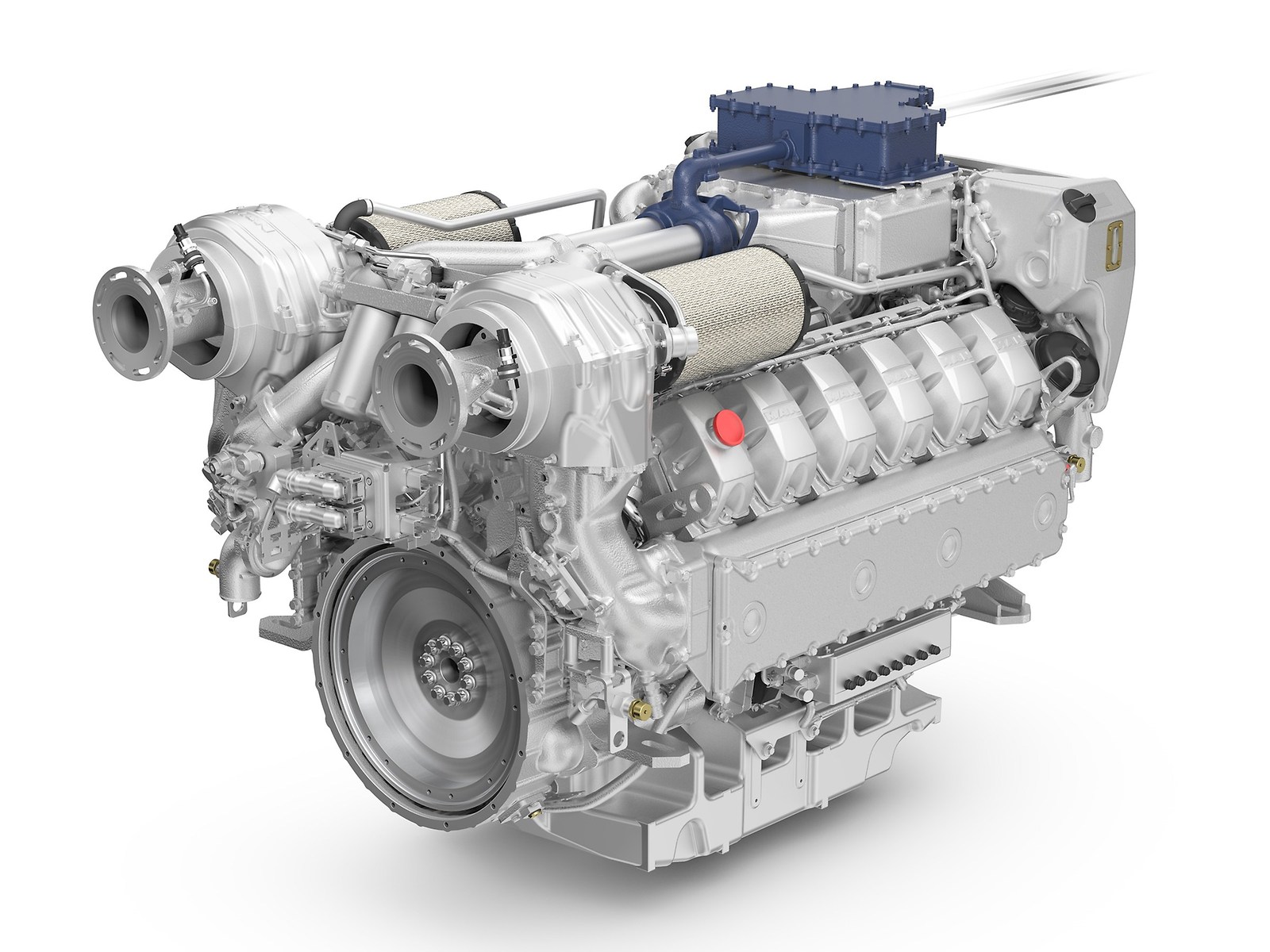

MAN D2862 (light / medium / heavy duty)

Cylinders: 12

Displacement: 24.2-liter

Bore: 128 mm

Stroke: 157 mm

Output: 1,029 – 1471 kW / 749 – 1, 066 kW / 551 – 735 kW

MAN D2862 H2 Dual Fuel

Cylinders: 12

Displacement: 24.24-liter

Bore: 128 mm

Stroke: 157 mm

Output: 749 kW

AUXILIARY ENGINES (CONSTANT SPEED):

MAN D2676

Cylinders: 6

Displacement: 12.42-liter

Bore: 126 mm

Stroke: 166 mm

Output: 190-445 kW

MAN D2862

Cylinders: 12

Displacement: 24.24-liter

Bore: 128 mm

Stroke: 157 mm

Output: 600-800 kW

MAN E3262

Cylinders: 12

Displacement: 25.78-liter

Bore: 132 mm

Stroke: 157 mm

Output: 500-580 kW

SCR SYSTEM

Exhaust gas aftertreatment solutions from MAN Engines

Exhaust gas aftertreatment from MAN Engines

To comply with the most important global emission guidelines, MAN Engines offers its customers numerous and flexible solutions for emission reduction. Together with its partners, MAN Engines can provide a wide range of variants for exhaust gas aftertreatment, from exhaust gas recirculation to diesel particulate filters and even SCR systems. As a result, we can provide you with solutions which are tailored to your specific requirements. Our engines thus satisfy the most modern emissions requirements, such as EU Stage V or US Tier 4, while also allowing for emissions downgrades in countries with less strict emission requirements. As customers you also benefit from the high quality of the components used, which have been proven not just in engines from MAN Engines, but also hundreds of thousands of times in the large-scale production of MAN commercial vehicles.

Exhaust gas aftertreatment (EAT) with SCR

Modular exhaust gas aftertreatment (EAT) from MAN Engines excels due to its compact design and high flexibility in restricted installation spaces. It allows for a wide range of installation possibilities and system integration tailored to specific customer needs, as the individual components can be positioned differently. Modular EAT is available over all segments and for many different applications. The centrepiece of the EAT is an SCR catalytic converter (selective catalytic reduction), which helps to reduce the nitrogen oxides (NOx) in the emissions in a targeted manner. To do this, a 32.5 percent AdBlue© fluid solution is metered in an SCR mixer and then injected continuously and directly into the exhaust tract. There, the solution reacts with the nitrogen oxides and converts them into water (H2O) and harmless nitrogen (N2). The system can either be used by itself, as SCR-only, or combined with other components such as a DOC/DPF (diesel oxidising catalytic converter/diesel particulate filter), to cover many different emission guidelines.